Success Stories

Our Global Reference Projects That Speak for Themselves

Over the past years, we’ve had the opportunity to work with numerous inspiring companies – supporting many of them in building stable and reliable electrical power supplies. Throughout every project, our mission has remained clear: we help our customers invest in a secure and sustainable future. Our clients benefit not only from the reliability and longevity of their investment but also from our commitment to using resource-efficient materials and environmentally conscious production methods – reducing the ecological footprint of every system we build

At the Heart of Every Major Technical System Lies Reliable Power

With over 40 years of experience, innovative ideas and a passion for precision, we create systems that set benchmarks for safety – for both people and machines.

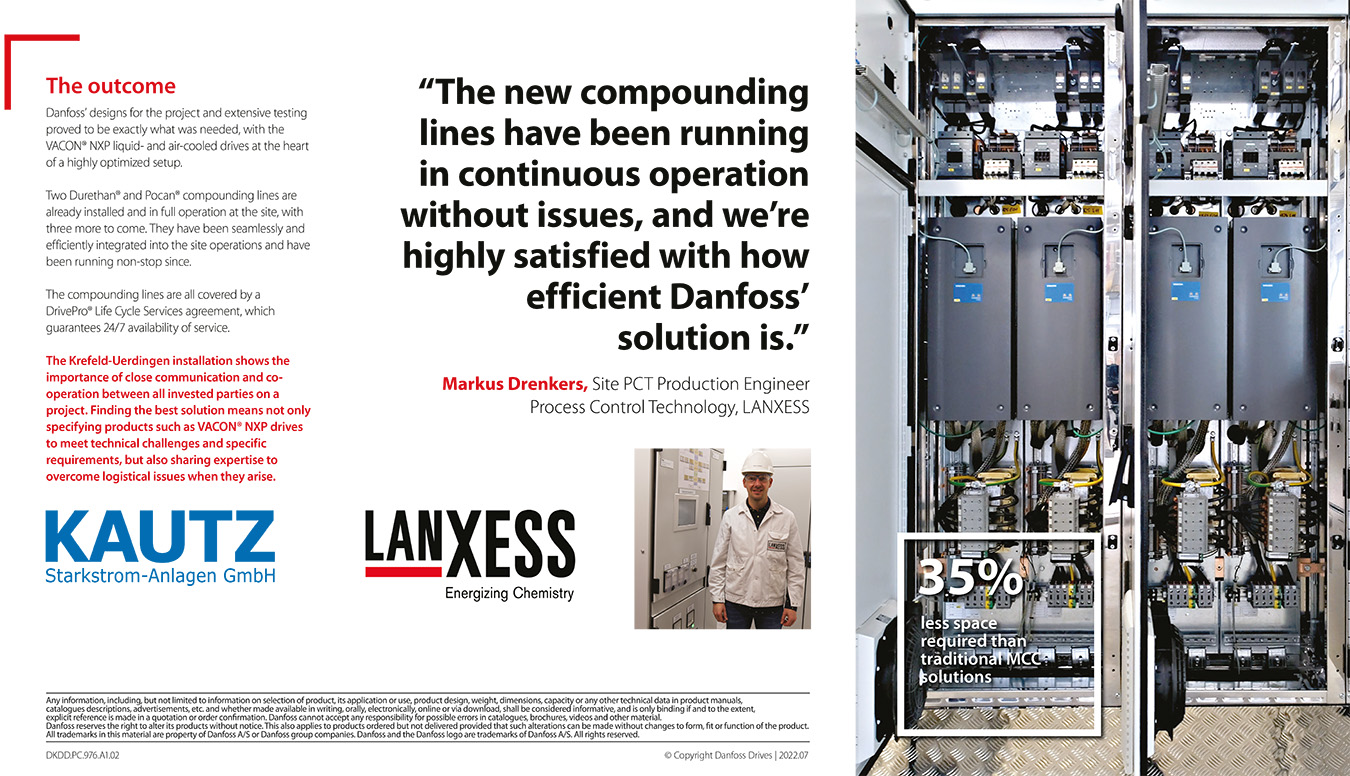

LANXESS

The challenge

At the LANXESS High Performance Materials site in

Krefeld-Uerdingen, Germany—its largest production

facility—additional compounding lines were needed

to produce engineering plastics for the automotive

and electronics industries.

This project comprised the new electrical

infrastructure for 5 compounder lines and a total

connection power of 9.4 MW. Planning for the project

started in 2018, but there were a few key challenges to

overcome.

• The LANXESS project required close coordination

between multiple parties to ensure that everything

ran smoothly, meeting deadlines

• Particularly noteworthy were the factory acceptance

tests at Danfoss Drives, the System Integrator and,

most recently, on the finished compounding lines at

LANXESS, which were carried out under COVID-19

conditions

• Standardization of existing motor control centers

(MCC) from 500 V to 400 V for the new

compounding lines. These new MCC cabinets with

integrated Danfoss drives for 400 V mains supply

were designed as a new LANXESS standard together

with the System Integrator, KAUTZ Starkstrom

Anlagen GmbH in Trier, Germany. Thanks to close

cooperation, potential difficulties were eliminated

The solution

Working in close co-operation with the team at LANXESS and several third parties, the engineering and design of the drive project was handled by the Danfoss Centre of Excellence (CoE) in Germany, which engineers individual customer-specific drive application requirements. The CoE team supported the entire project from order receipt through to the final Factory Acceptance Test, Site Acceptance Test and start-up support. 24/7 guaranteed service with DrivePro® Life Cycle services Danfoss recommended VACON® NXP Liquid Cooled 12-pulse NFE drives for AC motor speed control. These drives offer a compact footprint in comparison to air-cooled drives, high efficiency, and low noise level during operation. Positive past experience with liquid-cooled Danfoss drives and VACON® HXM120 heat exchangers prompted the LANXESS team to integrate the transformers in this project into the liquid-cooling system. This decision contributed greatly to the increase in overall energy efficiency, consequent reduction in energy costs, and low carbon footprint of the project. The compact size and simple installation of the VACON® NXP units streamlined the engineering remarkably, saving both time and money. Danfoss also supplied 40 VACON® NXP Air Cooled drives for auxiliary units such as conveyors, pumps, and fans. Those were fully integrated into the LANXESS standard cabinet 400 V / 500 V / 690 V MCC in Modul K - LXS design. This new future-proof integrated design required 35% less space than the traditional MCC solutions

GRIDNOVA – Wood Instead of Concrete, sustainable successful

A Step Into the Future

Traditionally, Germany has relied on concrete for transformer stations, especially in the energy sector. But times are changing: the future of energy technology is not only efficient but also sustainable. Energy systems of tomorrow are being designed without climate-damaging insulating gases and increasingly built with renewable materials such as wood. This is where GRIDNOVA – Sustainable Energy Center makes a powerful statement: it’s not just a functional building, but a symbol of change, sustainability, and innovation. By using certified timber construction instead of CO2-intensive concrete, GRIDNOVA sets new standards in sustainable infrastructure, combining environmentally friendly plant technology with forward-thinking design.

What Makes GRIDNOVA Stand Out

• Our Energy Centres connect distribution grids with consumers.

• Sustainable building materials like wood significantly reduce the CO2 footprint.

• Air-insulated

switchgear eliminates harmful insulating gases.

• Integration of renewable energy sources and

intelligent storage solutions increases efficiency and flexibility.

• Smart energy management ensures

reliable power supply.

• Sustainable construction and certified timber architecture instead of CO2-heavy

concrete.

• Sustainable technology – highly efficient medium- and low-voltage solutions. • Sustainable

operation, digital control, storage and service from a single source.